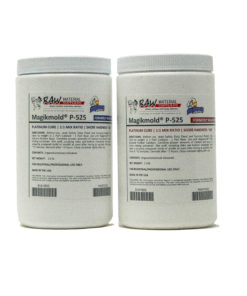

Magikmold® P-540T Translucent Platinum Cure Silicone Rubber

$39.00 – $692.00

Magikmold® P-540T is a platinum-cured, room temperature curing (RTV), translucent silicone rubber designed for the manufacture of high-performing, flexible molds.

Available in 4 kit size options.

FREE SHIPPING ON ALL SIZES. ONLINE ORDERS ONLY.

FOR INDUSTRIAL/PROFESSIONAL USE ONLY.

Magikmold® P-540T is a platinum-cured, room temperature curing (RTV), translucent silicone rubber designed for the manufacture of high-performing, flexible molds. This two-part (Catalyst & Base), liquid silicone rubber has a Shore Hardness of A40, a pour time of 90 minutes, and a demold time of 24 hours.

Magikmold® P-540T molds are commonly used to cast the following materials:

- Urethane (polyurethane) plastic and rubber

- Plaster

- Polyester Casting Resin

- Cement, Concrete

- Epoxy

- Soap

- Wax

- Low-Melt Metals

Release agent is not necessary for casting most materials into Magikmold® P-500 Series molds, but for longer mold life with epoxy, polyurethane or polyester resins, a barrier coat or release agent (e.g., Stoner E-236 Urethane Mold Release) is recommended.

This is a pourable rubber, but it can be easily thickened with silicone thickener for brush-on application.

FOR INDUSTRIAL/PROFESSIONAL USE ONLY.

Physical Properties

| Type | Platinum-cured (addition-cure) |

| Mix Ratio by Weight | 1 Part Catalyst : 10 Parts Base |

| Shore Hardness | A35 – A40 |

| Pour Time | 90 min. |

| Demold Time @ 77°F | 24 hr. |

| Cured Color | Translucent |

| Mixed Viscosity | 38,000 cP |

| Specific Volume | 26.6 in³/lb |

| Specific Gravity | 1.04 |

| Tensile Strength | 438 psi |

| Elongation | 296 % |

| Die B Tear Strength | 98.6 pli |

| Die T Tear Strength | 32.9 pli |

CURE INHIBITION: Contamination from amines, sulfur, tin compounds, polyester resins, some paints and some silicone rubbers may inhibit surface cure of this product. Perform a test cure on an identical surface to determine that complete curing and good release are obtained.

Product Literature

Technical Bulletin: Magikmold® P-500 Series Technical Data Sheet

Safety Data Sheet: Magikmold® P-540T Catalyst | Magikmold® P-540T Base

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| MIX & CURE INSTRUCTIONS | READ SAFETY DATA SHEET BEFORE USE. READ TECHNICAL BULLETIN FOR FULL PRODUCT INSTRUCTIONS. Before use, be sure that the Catalyst and Base are at room temperature (~73°F) and that all tools are ready. All mixing and curing should be done in room temperature conditions. Read all product labels to determine the correct mix ratio and if the product requires stirring or To ensure a bubble-free mold, it may be necessary to deaerate the liquid rubber under vacuum at 28-29 inches mercury. Pour the rubber as soon as possible after mixing/vacuuming. At room temperature (~73°F), this rubber cures to full hardness in the specified demold time. At higher temperatures, they cure faster. At lower temperatures, more time may be needed to reach full hardness. |

Related products

Platinum (Addition) Cure Silicone

Platinum (Addition) Cure Silicone